Why own development?

Because I own a short runway (236m), and due to the complex and fragmented surroundings around the runway, as well as the higher altitude (635 AMSL), I have decided to modify my aircraft for STOL so that they can take off from such a short runway with sufficient power reserve and the ability to climb over a nearby high obstacle.

I also needed lower noise emissions to successfully coexist with local residents, which is a requirement that is reflected in every aspect of my creative work.

How to turn theory into practice and why don't ordinary manufacturers do it?

The biggest noise from a high-performance aircraft is caused during takeoff and is usually due to an unsuitable small-diameter propeller, high propeller speeds, and poor propeller blade settings. Poor propeller blade settings mean that one or two blades are twisted compared to the others (standard tolerance is 0.3 degrees), an unsuitable profile and its change on the propeller blade length, insufficient propeller blade stiffness (when one or more blades wobble differently than others). Noise is also produced by the unsuitable gear reduction ratio of the engine reducer together with the small propeller diameter, and finally, by the unsuitable exhaust system and its damping.

According to theoretical principles, I need a propeller with the largest possible diameter, preferably with the smallest reasonable number of blades and the lowest speeds to achieve the highest efficiency in transferring power from the engine to the air. This means that I need an engine with a different torque curve than the typical aircraft engines offer.

Aircraft manufacturers prefer compact aircraft dimensions, which means a small distance of the propeller axis from the ground. At the same time, they most commonly use one of the very old technology: Rotax 912 ULS 100HP aircraft engines. Because this engine is easily stoppable, light, and relatively powerful for its weight, it is water-cooled, air-oil-cooled, and fueled. Therefore, it is also less susceptible to overheating with the correct and already proven installation and normal use. The disadvantage of this engine is very low torque peaking at 5500 engine rpm, where it provides only about 128Nm on the engine's crankshaft. If you want to have a reduction gearbox, then at a reduction ratio of 2.42:1, the propeller output shaft speed is 2272 rpm and 310 Nm. The engine rpm is still unnecessarily high and the engine has a low torque!

Can it be done differently and better?

It is possible to install a more powerful engine with significantly higher torque. A big advantage would be if the propeller axis is as high above the ground as possible, to allow for a larger diameter propeller to be installed. Let's compare the power units with their respective propellers as a whole!

The Rotax 912 ULS 100HP gives 95HP at 128Nm at 5500RPM with the commonly mounted propeller of 1680mm.

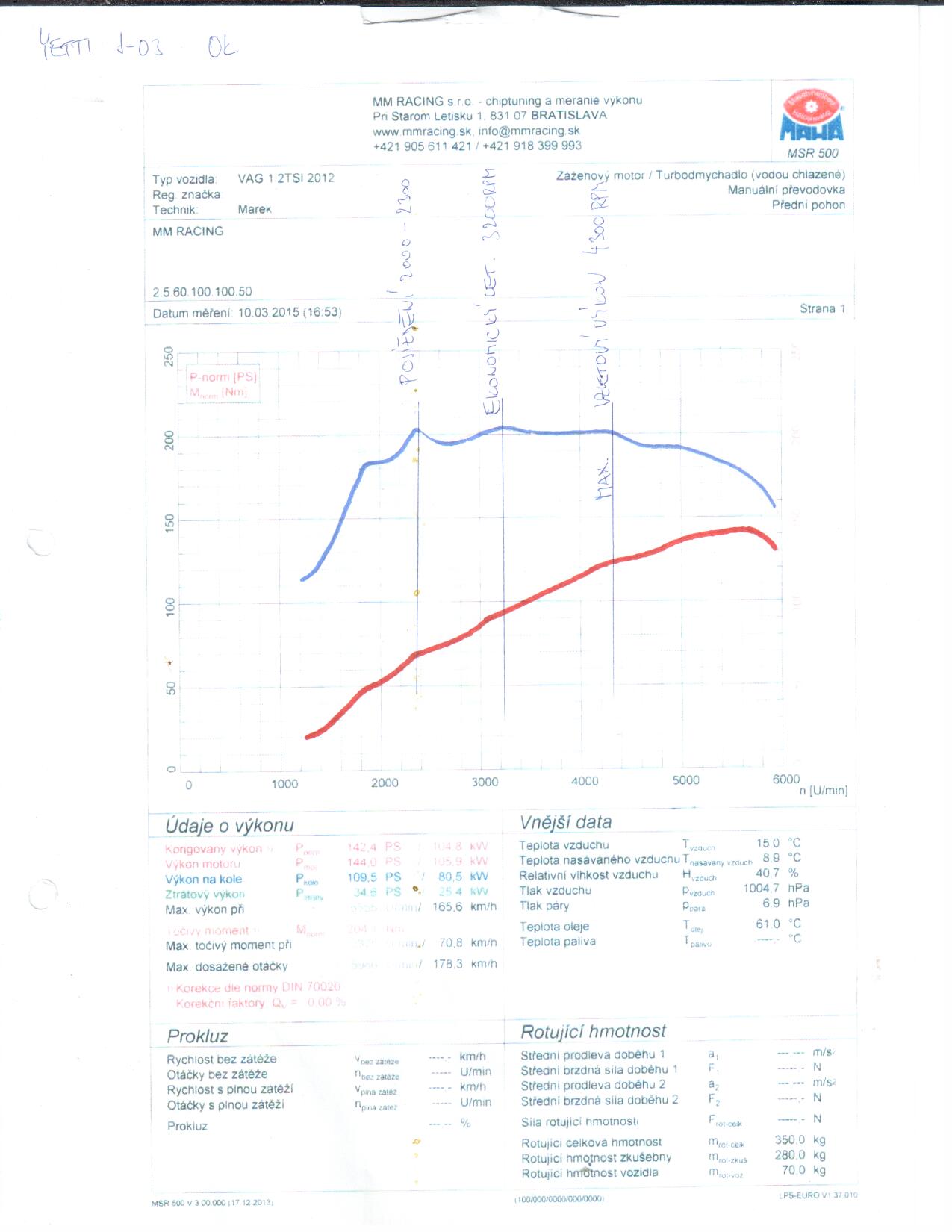

Compared to the CBZB 1.2TSI engine with 120Hp/210Nm/4000RPM and a propeller of 2060mm.

However, the best comparison of the delivered power and torque transmission is behind the gearbox on the output propeller shaft!

The Rotax 912ULS gives 95Hp at continuous power and a reduction ratio of:2.42:1 with 2272 propeller rotations and 310 Nm.

The 1.2 TSI CBZB in the modification of 130HP and 4600RPM at this continuous power gives 2300 rotations on the output shaft of the gearbox and 400Nm.

Thus, lower rotations - higher efficiency of power transmission into the air and a significantly higher torque by one quarter in favor of TSI. Moreover, the difference in power is 20% higher in favor of the 1.2 TSI with 118Hp at 4000RPM. By lowering the rotations, we also reduce the consumption of the 1.2 TSI engine. Additionally, we gain one square meter of more accelerated air around the aircraft compared to the volume of both considered propeller circles. This allows:

Faster and shorter acceleration, faster and shorter takeoff on a shorter runway, and significantly greater - steeper angle of climb.

Greater efficiency and maneuverability of the aircraft from more blown tail surfaces during takeoff. This can be compared to increasing the surface and deflection of the rudder and elevator, which will then have greater authority, but without unwanted detachment of the airflow.

Better maneuverability of the aircraft during landing, where by adding a small amount of throttle, you can adjust the aircraft's maneuverability. (for advanced and competitive pilots familiar with this piloting technique)

The above is not just theory, it has also been tested in practice on identical aircraft!"

Why not use existing engines?

Acquiring an affordable and powerful aviation engine with around 120-140 horsepower and 200-250 Newton-meters is currently practically impossible. The most well-known and lightest Rotax 912 ULS costs 450,000 Czech crowns, and its more powerful sibling, the R 915 with 140 horsepower and 150 Newton-meters, can be purchased for just under 1 million Czech crowns. For that price, I could have a complete aircraft, and still have enough left over for a different engine!

Radial engines with good power and torque from Mr. Werner are not suitable for my aircraft. They are more suitable for replicas, where they are a beautiful decoration for the aircraft.

UL Power engines have a maximum power declared at around 3000 RPM, which only shows that the engine manufacturer did not understand how to transfer engine power to the air. (High RPMs produce losses converted to noise and the low efficiency of a small diameter propeller... because a propeller with a large diameter cannot be used, unless it was designed for supersonic speeds, and there are no such propellers for ultralights yet.)

Converting Suzuki 1.6 16V engines with a power of approximately 105 horsepower from the Drahošes is not an option for me. They are much less powerful compared to the 1.2 TSI engines, without a turbo and therefore with a low torque, and with an unsuitable power characteristic for me, with a torque that peaks too high and are already technologically outdated. They weigh the same as the 1.2 TSI. The complete installation is around 100-107 kg.

Converting Subaru EA 81 engines with a power of approximately 80 horsepower are long past their prime, although they had nice reducers with gears at one time and were very, very reliable, but heavy! The complete installation of the engine in the aircraft was often over 110 kg.

This could continue with various engines like Strádal 1200, VW, Porsche, BMW 1200, diesel Peugeot, Walter, Praga, D-motor, and other new types of engines... Either they do not have the required power and especially the required torque, or they have it in a high range of RPMs, or they are outrageously expensive and often unreliable."

The propellers available on the world market are unsuitable for Ultralight 600kg? Why?

Buying a suitable in-flight adjustable propeller with a diameter of around 2-2.10 meters, weighing around 12kg, and costing around 200 thousand CZK for an engine with a power of 120-140 hp and 450 Nm at secondary shaft, such as the 1.2TSI, or a similar engine with a different atypical torque distribution to the engine power, is impossible worldwide! Most propellers are too heavy, weighing much more than 20kg, or they do not have sufficient diameter or cannot transmit power of 120-140Hp and a torque of around 450Nm!

From this, a simple equation comes out for me: what I do not make myself, I do not have. I have to make or convert a powerful engine with high torque at operating speeds and a corresponding in-flight adjustable propeller that can transfer 450 Nm of torque to the air. Manufacturers compete to have the most powerful engine. Paper can handle many things, actually everything, but engine power in real operation often shows significant deviations from the declared power. Power without the appropriate torque and the correct torque curve characteristics is often only presumed or calculated and rarely fully utilized in practice. Especially when we have a propeller with an insufficient diameter, which is given by the installation height of the aircraft, the height and strength of the nose landing gear, or technical regulations. The engine power significantly decreases with increasing temperature and altitude.

For example, the Rotax 912S (manufacturer's declared power 100 HP) already has about 20% lower power at 25°C and an altitude of around 2000 meters AMSL. The Rotax 914 Turbo without an intercooler is a sluggard who fades immediately when the overpressure and overheated air from the turbo enters the intake, when the electronic control reduces power and closes the increased filling of the engine. The UL power 390i engine needs 140HP at 3300 RPM to deliver maximum power. Really? What propeller with what diameter, how many blades, and how efficiently will it transfer this power to the surrounding air at these high speeds of 3300RPM?!!

In my e-books, I present detailed instructions and know-how, and I want to show that you too have the same opportunity to modify (convert) any available engine similarly or even better than I do.

Personally, I convert the most accessible and lightest engine in the Czech Republic, the Skoda 1.2 TSI, EA111 (CBZA, CBZB, CBZ0) with an eight-valve mechanism, which is modified to 120-144 HP with a torque of approximately 210-230 Nm. Power can be tuned to different propellers and speeds as desired.

The weight of the engine with the gearbox and the entire assembly is around 100kg to 107kg, depending on the assembly. Approximately 6-7 kg can be saved if you do not use an electric starter and an oversized 18Ah battery for it. The engine can be easily started manually by turning the propeller, and if you install a LIFEPO4 5Ah battery, you will save another 5kg of weight."

The NG6 aircraft, "DREAMTRAINER-FZ", from the manufacturer ROKOAERO

(similar to the Bristell type), is capable of traveling at 220 km/hour with the 1.2 TSI engine with a 2.0:1 reducer, at 4200RPM in the air and 2100RPM on the ground with adjustable Meglin propellers.

With an in-flight adjustable three-bladed propeller with a diameter of 2060 mm, the aircraft can reach speeds of up to 250 km/hour at 4500RPM in the air adjustable propeller and keep 2250RPM. Such a cruising speed at such low engine RPMs - emphasizing 4500 RPM and half the propeller RPM, or 2250 - is not achievable by other ultralight and LSA aircraft with side-by-side seating arrangements.But you need to fill up with 100-octane gasoline!

I achieved this excellent result through hard, long-term, and targeted work on the conversion and modifications of the engine and in-flight adjustable propeller, which are finely tuned to achieve the intended purpose.

This includes:

The low weight of the in-flight adjustable propeller with a diameter of 2060 mm, which is only 10.3 kg.

The low weight of the engine installation, approximately 105-107 kg.

Choosing suitable propeller blade shapes, profiles, and custom carbon-fiber manufacturing with a stainless steel leading edge that weighs only 999 grams.

Choosing a suitable oversized center of the propeller with precise mechanics and excellent materials.

Short takeoff and landing (STOL) capability with only 150m of runway length.

High cruising speed of 220-250 km/hour.

Spartan aircraft equipment without paint and parachute rescue system.

Aicraft 1.2TSI engine at NG6 VIA from ROKOAERO 600kg MTOW ULTRALIGHT.

Yetti J-03 STOL Aircraft

The Yetti J-03 aircraft, equipped with the 1.2 TSI engine and a 1:2.4 reduction gearbox (version 1.0), is capable of taking off from a runway as short as 20-40 meters, depending on the surrounding air temperature, at 5500RPM. In this configuration, the aircraft was able to climb at such a high angle of attack that it exceeded the maximum limit of 30 degrees. Even as a test pilot, I was not entirely confident in converting the aircraft from this high angle of attack to a descent at low altitude in the event of a sudden engine failure. Operating the aircraft without an adjustable propeller results in unnecessarily high RPMs, around 4200-4500RPM, and a cruising speed of around 100-110km/h. This also increases fuel consumption unnecessarily. In fact, I did not need a race or competition aircraft with higher fuel consumption.

Therefore, I created a version 2.0 of the gearbox with a reduction ratio of 1:2.0 and installed a large diameter adjustable propeller in-flight. This allowed for cruising speeds of 110-150km/h at the aforementioned RPMs. However, I ultimately removed the adjustable propeller because I was concerned about damaging it during competition flying. The Yetti is, after all, a STOL aircraft with lower speeds (Vne is 182km/h), and an adjustable propeller would tempt me to fly too fast, risking damage from branches or flying rocks, and it is not cheap. For bush flying, cheap fixed-pitch propellers are more suitable.

I am satisfied with the 2100mm wooden fixed-pitch propeller developed and manufactured by Mr. Wolner. With the Wolner 2100mm propeller and the 1.2 TSI engine, the Yetti J-03 can take off from 25-45 meters and land in 85 meters, which is sufficient for a STOL aircraft. Short takeoff and landing demonstrations"

Results of the development of "Zejda" propellers:

"Zejda 1" Propeller Individually built and adjustable in flight, the three-blade "Zejda 1" propeller with a diameter of 2066mm has sword-shaped carbon-reinforced blades with a reinforced main beam inside the propeller blade and a stainless steel leading edge, with a total weight of 10.3kg. It is designed for the fast aircraft "DREAMTRAINER-FZ" to achieve maximum cruising speeds around 220-270km/h and at the same time short takeoff on max. TOW 600kg from any surface length of 236m. The complete assembly of the adjustable propeller blade of the "Zejda 1" propeller is included.

The propeller blades are twisted longitudinally by 30 degrees. The weight of each individual carbon propeller blade is 999g. The weight of the propeller blade carrier made from the highest quality available steel is 999-1000g. The weight of the complete assembly of the blade and carrier with bearings and securing nut, as it is mounted into the propeller hub, is 2718g. From the above, it is apparent that the largest weights of the propeller are up to a radius of 120mm from the center of the propeller. This minimizes the gyroscopic effect of the propeller to the same value as commonly used adjustable propellers.

By balancing, fitting, and assigning individual components in the assembly of the complete propeller blade insertable into the propeller hub, I achieved a less than 1-gram deviation between the other fully assembled blades with the carrier, both bearings, washers, nut, and locking screws. Subsequently, I statically balanced the propeller and performed a propeller test of the individually built propeller according to the UL regulations.

Afterwards, I disassembled the propeller again and checked the individual components for tension, wear, microcracks, cavitation, and other phenomena. I carefully reassembled the propeller and conducted a repeated test in which it passed. The propeller is now flying in normal operation and its lifespan is being tested. A photo of the propeller can be found in the gallery on the main page.

Vrtule Zejda 1 - třílisté provedení, plně zkompletovaná vrtule bez dýnka a kužele po vyvážení.

"The propeller 'Zejda 2' is a two-bladed design with a diameter of 2030mm and a total weight of under 8kg! This propeller enables the TECNAM P 2002 Sierra aircraft to fly faster up to 220 km/h even without flaps, climb faster and at a steeper angle with a short takeoff and landing distance."

Results of my work:

This is what helps me operate airplanes on any surface and safely take off and land on short runways with my modified aircraft.How did I achieve this?

By selecting the appropriate type of aircraft, the TECNAM P 2002 Sierra, which is a highly maneuverable and powerful machine, with limits of 20kt and 22kt for rear and crosswinds, respectively, which are not exceeded by many great GA aircraft. Additionally, the Sierra can be further modified...

The YETTI J-03 aircraft, with a 1.2 TSI engine version 2.0, a Wollner 2100mm propeller made to order to match the engine's performance characteristics and torque. Wortex generators across the entire wing span. Bush landing gear with large wheels.

With the "DREAMTRAINER-FZ" aircraft, which is actually an NG 6 Via or similar Bristell aircraft, I achieved higher engine performance, higher engine torque, a version 2.1 gearbox, a much higher propeller installation height with a larger diameter, manually retractable flaps at a very high angle, and an enlarged rudder with a corner relief and an in-flight adjustable propeller "Zejda1."

By fitting the aircraft with fixed and in-flight adjustable converted propellers with a significantly larger diameter (2066-2100mm), better shape and blade profile than those offered by original and commonly available manufacturers, I achieved higher efficiency in every engine operating mode.

During take-off, when the aircraft briefly produces higher noise, I focused on having the aircraft take off with a demand for higher power at lower RPMs, for which the engine gearboxes had to be reworked, significantly reducing the noise footprint! The propeller's scimitar blades eliminate the noise footprint and increase the efficiency of the propeller by allowing the airflow to gradually flow onto the propeller blade and reduce resistance.

By fitting the aircraft with vortex generators - turbulators - which, when properly placed in front of the control surfaces, increase the aircraft's maneuverability, and when placed along the wing, increase lift and allow for flying at a much higher angle of attack at lower airspeeds. Wortex generators have similar or equal effectiveness to slots, but without affecting the wing's construction. Turbulators increase maneuverability in tailwinds but also increase fuel consumption and reduce maximum cruising speed. Turbulators also worsen the glide ratio.

By lightening the aircraft of unnecessary things, purchasing higher-quality sports and racing components, filters, spark plugs, oils, oil and fuel additives, and Bishop's original lubricants, pumps, Goldfren brakes, etc.

By regularly mowing and rolling any other surfaces with a fully inflated roller after rain to reduce rolling and friction resistance and fully lighting it with guiding lights. Allowing for more precise budgeting and shorter takeoffs and landings, as well as a significant increase in operational safety.

By converting the automotive engine 1.2 TSI CBZA and CBZB into an aircraft engine, as described on Aeroweb and my blog at a time when the precise technical conditions for the UL MTOW 600kg category were not yet known, I achieved a lightweight (100-110 kg depending on configuration and use or rejection of the electric starter) and powerful engine."

The Rotax 915is engine versus the 1.2TSI

The 1.2 TSI engine is modified to produce 120-140HP and, with the use of a large-diameter, in-flight adjustable propeller, it is comparable in terms of power to the Rotax 915 IS engine with a standard propeller diameter of up to 1750mm.

While the wealthiest pilots are only now buying or considering purchasing the Rotax 915is engine for their aircraft, at a cost of around 40,000 USD/EUR without installation, those of us who have the 1.2 TSI engine installed in our planes have been flying with performance that other pilots can only dream of. Many pilots will not be able to attain the Rotax 915is engine for a very, very long time!

Perhaps only on a completely worn-out or crashed aircraft will the Rotax 915is engine become available, and even then it will still be very expensive, while the 1.2 TSI engine will always cost a fraction of the price even after conversion. Therefore, the conversion of an automobile engine with an in-flight adjustable propeller appears to be the most efficient and cost-effective way to achieve a motor unit with the same or even greater performance compared to the Rotax 915is engine with a commercially available propeller. And the effort to build the 1.2 TSI engine and the large in-flight adjustable propeller is definitely worth it! The power and acceleration are indescribable..."

Aicraft engine 1.2 TSI 120-140HP/230Nm"

Below is a video of a complete conversion of the 1.2 TSI, EA111, CBZA version 2.0 with a Zejda spur gearbox and a 2.0:1 gear ratio. Currently, I have produced a motor with a 2.2 spur gearbox version with lower weight, higher rigidity, and a greater axial distance between the shafts, allowing for the installation of a larger diameter propeller!

Three 1.2 TSI engines with a 2:1 reduction ratio and a 62mm wide Gates polychain flat belt from Gates have already been installed in three aircraft. The power-to-weight ratio of the engine is very important depending on the aircraft and the installation you plan to use it for. It also depends on how you modify and tune the engine and what turbocharger you use. A lightly tuned Stage 1 engine with the original turbocharger produces around 140 hp at 5000 RPM with a torque of around 205 Nm.

The power-to-weight ratio is 140 hp to 107 kg, or 1.30 horsepower per kg, or 0.96 kW per kg. If you decide not to use a starter, you can achieve a nice 1.0 kW per 1 kg of the total weight of the engine installation!

Some tuners can modify and tune the 1.2 TSI, EA211, 16-valve engine to Stage 3, up to 205 hp at 5500-6000 RPM. They use a turbocharger from the 1.4 TSI, but the torque value is lower, about 200 Nm. Such a setup would require the engine to run at high RPMs for a long time, resulting in high fuel consumption, and would be more suitable for racing or competition aircraft for SUPER STOL flying. Of course, the risk of something going wrong with an engine operated at high RPMs is higher, not to mention that such power must be cooled, which in turn increases weight and requires larger radiators."

Neváhejte a kontaktujte nás. Rádi Vám pomůžeme. Volejte na číslo: +420 603 107 704

nebo nám pošlete e-mail na: filip.zejda@seznam.cz

tarifs pour la formation des pilotes et la location d'avions. 2020

Pdf soubor ke stažení zde...

Prévisions météorologiques pour nous.

préparation avant le vol.

Odkaz zde...